Comprehensive info book about printers

Comprehensive info book about printers

Top info book on printers: Printers are also an essential part of various industries. Most of the sectors are still using traditional methods to print the designs on different materials or objects. The other conventional methods are a bit inexpensive than printing technology. But the printers for industrial use can decrease the workforce and consumption of time. You can print the design on various materials in less time than traditional methods like a painting. So you need a printer to print the industrial tasks on steel sheets, plastics, cardboards, or textiles. Which printer to use in industry? For industrial use or to print the designs on raw materials like plastics, steels or cardboards you cannot use the traditional inkjet or laser printers. It depends on the type of industry. So let’s have a look at some kinds of industrial use printers.

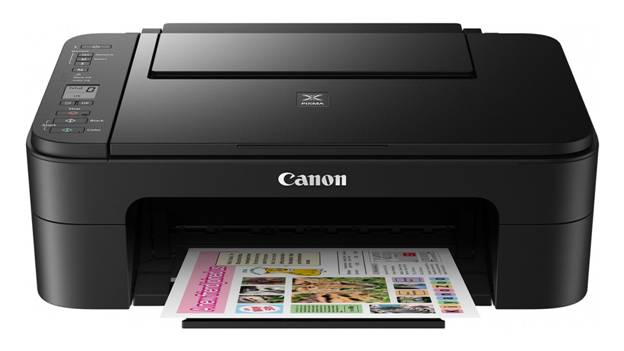

The decision which you will make between an inkjet and a laser printer will be determined by what you need to use the printer for. There are people who do print a few pages every year or do print photos frequently than the documents. There are people who will print text reams but will print photos rarely. In most cases, the inkjet printers are considered to be a better fit for anyone who will not be printing on a frequent basis. The inks do cost more on per page basis although the refills do cost less when compared to the toner. The inkjets are best suited for use in small spaces while the laser printers are suited for use in larger spaces due to their big size. Laser printers do offer an affordable method of printing lots of text heavy pages. It is also known to be much faster and does offer a smudge free and finished page within seconds.

What is a 3D printer? 3D printers are similar to inkjet printers where the designers can make their rapid prototypes within a few hours by using various materials like plastic, aluminium, cardboards, steel sheets etc. This incredible technology was launched in the early 1980s. Before the discovery of 3D printers, the companies were facing too much difficulty to create a model of their ideas which looks similar to real. They used to hire an artist and designers to create designs on CAD software and then create models by using woods and small pieces of cardboard and plastics. They could take weeks to make the accurate model of the object. But since the launching of 3D printing technology, the task gets more comfortable. The idea of 3D printing technology was named rapid prototyping that means creating or developing models by automated methods within a few hours or days.

Is the A4 format sheet similar to 8.5 x 11 inches? No, there is a difference in size. Only the American countries are using 8.5 X 11 inches sheets as the standard letter size. The rest of the world uses A4 format to print their office documents, letters, etc. Whenever we have to use a printer paper, the size matters a lot. We cannot print a big image on small paper or vice-versa. Hence, it is better to check the size or resolution of the document you are going to print. It is quite essential to use the appropriate size. Hence we have mentioned a few above. You can select from all the sizes that we have mentioned above. Many manufacturers in the market can help you to purchase the best product at an affordable rate. Therefore, it is better to research before buying a one for you.

Safety is a major priority when cleaning the mono laser printer. Ensure that you do turn off and remove the power plug of the printer before you embark on the process of cleaning it. This will ensure that you do not run the risk of being electrocuted. You can consider putting on latex gloves and a mask to help prevent the small and fine toner particles from getting stuck on your body skin, eyes, nose, and ears or into your lungs. Ensure that you always keep the room windows open and turn off the fans or ACs off before you start doing any cleaning exercise.

There are no special tools that are needed in the 3D printing process. The parts are normally made directly on the platform that has been built layer by layer. This will lead to a completely unique set of advantages and disadvantages. The 3D printing process starts with the digital 3D model that is the physical object blueprint. The model is thereafter sliced by the software of the printer into a small two dimensional layer and thereafter converted into a set of instruction in the language of the machine which is the G-code for execution. It is important one knows that the 3D printer do vary by the process. For instance, the FDM printer do melt the plastic filaments and puts it down on the platform of printing by use of the nozzle which is a computer controlled high precision gun. There are also the large Industrial SLS machines that make use of the laser to help in melting the thin plastic or metal layers. The available type of materials does have a variation on the procedure. Plastics are considered to be the most popular although metals can also be 3D printed. Parts produced do have a wide range of physical and specific properties that range from rubber like to optically clear objects.

Many people research on what laser printer has the cheapest ink. It can be in two forms, dye base or pigment base. The cartridge type you go for will determine the ink form you will buy. A good number of inkjet printers do use dye-based ink since it is much more economical when compared to the pigment-based. It also does have an altogether higher capability regarding the production of vibrant and lively colors in prints and photos. One main disadvantage that comes with using a dye-based ink is it is very prone to smudging as it is not waterproof. It is not that durable and can fade after 25 years. The finish is crisper with pigment ink and does dry quicker when compared to the dye-based ink. Professional photographers and graphic designers do value the pigment-based ink much more than the dye-based ink since it is capable of printing archive text and pictures of top quality. It is UV and water-resistant, which allows it to last for a pretty more extended time. Discover even more info at printerever.com.